Products

Electronics Logs

For effective management of fleet operations Imar Corps electronic Logs software takes out the manual process and digitizes your statutory log compliance. This enables you to get powerful business intelligence reports and helps improving your efficiency manifold

Ship Management Software

Our Ship Management Software provides an efficient tool for managing crew operations and ensuring regulatory compliance.

Logiklu

Your dependable source for creative answers to your business’s needs. We propose LogiKlu because it is a potent sales pipeline automation product that integrates CRM and lead generation in one integrated, simplified workflow. This is because we are aware that sales automation is essential to meeting your sales targets.

ERP

We are your trusted partner for all your ERP business management system needs. With over two decades of experience serving leading global companies across various verticals, we bring the best business-oriented ERP services with high-quality customization, implementation, licensing, and maintenance.

Here’s everything you

must know about us

e.Soft is a leading-edge one stop IT solutions provider helping businesses grow exponentially. Using technologies’ magic wand, our magicians (tech experts) can transcend all your business ideas and needs to reality. With over two decades of experience in web apps, mobile apps, software development services, and various other IT solutions, we have helped more than 100 global businesses scale up. We are a family of technology veterans and with every passing year, this family only gets extended with more happy clients.

What our clients say

Nidia Smith

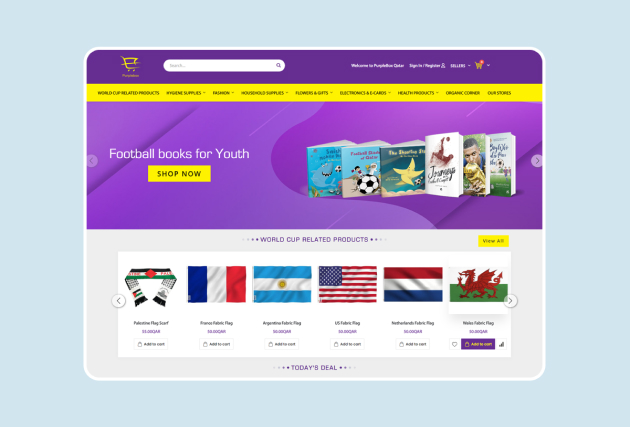

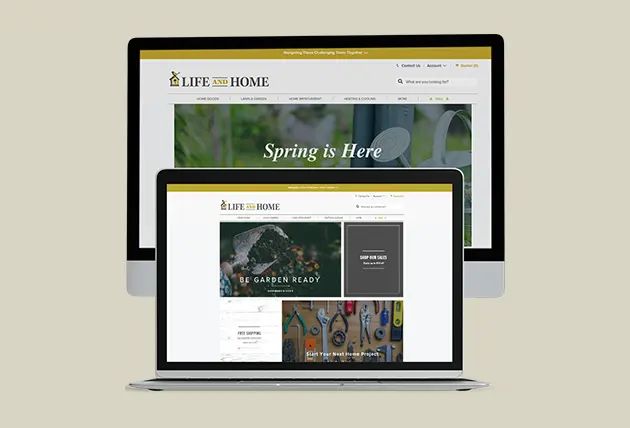

Operations Manager - Life & Home

Choosing e.Soft as our commercial partner has been one of the finest decisions we have made. They upgraded our business with value additions such as Customer service, Brand and Category Management services. I would recommend e.Soft mainly because of their genuine interest in exploring the possibilities of your business.

Rajat Wadhwa

SEO - ChannelSale.com

With a wide range of technological solutions and a highly experienced team they delivered excellent technical support to our business. They met our demands by providing undivided attention and support and made sure our business was scaled up successfully.

Steve Lipman

CEO- Web services of america inc

Web Services of America, llc

In 2006 I was asked by The CBS network affiliate in Boston to create a video application that was adopted for use with The Boston Marathon. It was a smashing success and could not have happened without e.Soft Technologies. Their team worked tirelessly in making this a first rate deliverable. In my experience, I have found them to be knowledgeable, creative, and valuable resources that I continue to use. Moreover, they are fine people with impeccable integrity.

Syed Abbas Murtaza Shamsi

Joint Secretary Manager

Shia P.G. College

At the time when we were facing grave adversities, e.Soft stepped up and resolved them with their technological proficiency. They supported our manual processes with a highly responsive and easy-to-use software. We have only benefited from their services and we wish to work with them again in the future.

Narendra Dev

President

Cupertino Networks

We have been collaborating with e.Soft for nearly 7 years now. They are nothing less than a family to us. During these years, they have greatly supported our business with extensive technical support. e.Soft is a valuable and reliable partner to us and we would recommend it to anyone who wishes to explore the true potential of their business.

Read our latest tips & tricks

Let’s know each other better